Quality is our top priority

We pledge to deliver the best quality produt to our clients and work towards it everyday.

We love manufacturing garments and we are best at it.

Designing unit equipped with CAD/CAM facility where new designs are made on the clients concept and also pattern making is done inhouse on client's requirement

Manufacturing plant is equipped with latest machines and employess with a decade and more experience. Embroidery and printing are inhouse which ensure shorter leadtime and better production saftey.

Quality is controlled and prodction floor is monitored for eficiency & saftey continously. Very effective metal control policy is maintained.

We understand what fast fashion is and we have adopted ourselves to deliver goods on time to meet the client marketing plan. We establish a transparent lead time beforehand so there are no deliveries postponed

Our manufacturing unit is the heart of our company with 100 permanent employees and operating all round the year.

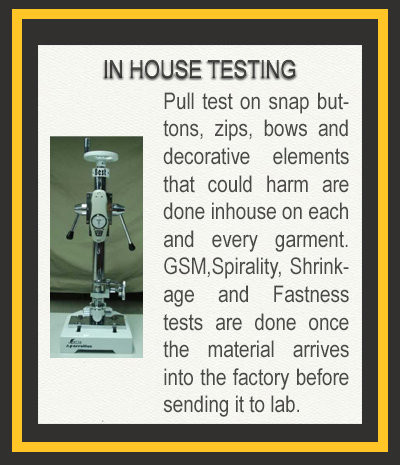

Cutting department is the beginning of production in the factory. Fabric received inside the factory is relaxed and prepared here for further processes. Our cutting section is equipped with 3 band knife machines for fast production. Cutting supervisor is responsbile for submitting the inhouse shrinkage, spiralirty and fastness report once the fabric is received.

Sewing deparment is divided into two sub divisions and they comprise 160 machines where 120 are operated daily and rest are used as a buffer. Our sewing floor consists of lines, which are shuffled based upon the style thats being produced. Complex styles like winter jackets with wadding & linings are sew by a single individual from start till end.

Inspection is done at the end of each process to prevent damaged parts to mingle in the good parts. Finally after sewing and trimming, a set of people visually inspect the garment in & out for any damages. After inspection the goods are again inspected one by one before pressing and packing. We make sure no damaged or inappropriate garment gets into packing line.

Apart from usual HR job Payroll administration, Employee benefits, HR management, Risk management - our HR also looks into wellness of the employees from ergonomic practices benifitting employees health, work-life balance and arranges a company picnic once a year to keep up with the bond between the employees beyond the workplace.

Design department is equipped with CAD/CAM machines. Assyst Bullmer CAD system from Germany and ORBITO CAD System from local vendor are used for patterning. New designs are made on demand from the client if needed or a pattern are drew on the spec sheet from the client. A cutter plotter is used for fast and reliable pattern output.

Sampling section is not a department itself but well experienced people who work for producing new product samples and headed by a individual. Sampling department is under direct control of our Managing Director.

Embroidery section is inhouse and equipped with two 20 head machines from barudan and Tajima. They save us a lot of time in production resulting in reduced lead time and high standard of metal control policy is maintained

Our printing section is a manually operated round printing press machine and it is loacted a couple of kilometers from the company. Printing is alos Oeko-Tex Certified & euqipped with waaste treatment plant for itself and all our current printing demands are met within our printing unit. Neck label (heat transfer) are not printed insted they are stickered and fused to the garment inhouse in the company.

Accesories section is responsoble for all accesories like button, labels and more. Also a store is maintained by the accesories department where all the goods are issued upon internal delivery form to make sure no accesory is misused or misplaced. One needle issued for the one needle returned is the needle policy maintained

From yarn to fabric, all type of process outsourced are followed by the fabric department. All kind of imports on special fabrics and fabric consumption are done by the fabric department. Also fabric department brings up new fabric materials to the designer table.

A seperate button section is establised as there is a regual need for snaps and zips. An isolated area for placing snaps paves better control over misplacement and mishandling, thus reducing contamination risks.

After final inspection steam pressing is done and garments are packed. Packing section has a airport type check up of each and every garment through the metal detector, ensuring no contaminated garment is packed in the boxes. A metal free zone is establised after the check up. Before final inspection the garments are checked for pull test and logged in.

We have a great collection of kids wear and below here are few of our garment

We are a member of Tiruppur Exporters Association and our company is a Indian Government recognised export house for trust and reliability.